Repairing Composite Structures

Automating Thermal Bonding Systems for Field Repair of Aircraft StructuresZIMAC laboratories, the industry leader in hot bonder solutions for field repair of composite aircraft structures asked WiTEST team to develop a solution to automate their product. The innovative and cost effective repair technology of these bonders uses surface heaters to provide a controlled temperature profile to cure the metal structures in an open environment in the field.

Avoiding the tradition heat treatment carried out in large size thermal chambers, the method provides a cost effective repair strategy for the aviation industry.

Managing high power heaters and temperatures exceeding hundreds of degrees, the application places mission critical and stringent reliability requirements on automation software. As the repair strategy and temperature profiles are optimized for specific structure details, the automation software is required to provide high degree of flexibility in temperature profile definition and use of resources such as thermocouples and heaters.

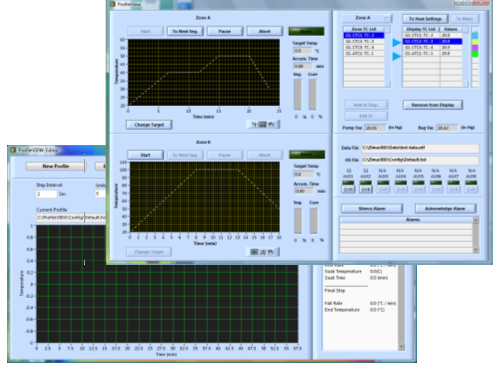

We developed a LabVIEW based solution deployed on Windows laptops and on Windows XP Embedded computers with a touch sensitive display. The test and control automation software allows full system-setup and generates the required temperature profiles using PID control. With a comprehensive live monitoring, data logging and reporting capabilities the solution also provides in depth alarm generation and alarm management features.

Working with several tens of thermocouples, pressure sensors and high power relays, our solution has proved itself to successfully provide a controlled temperature profile with all the safety, scalability and flexibility features need for this critical application.