Testing Automotive Parts

Production Testing of Automotive Electromechanical Assemblies with NI LabVIEW and CompactDAQProviding reliable and cost effective test automation software integrated with machine vision, actuators and sensors for temperature, current and vibration was the challenge trusted to us by Motion Pac International when it came to automate their equipment able to test different automotive electromechanical assemblies at the production floor.

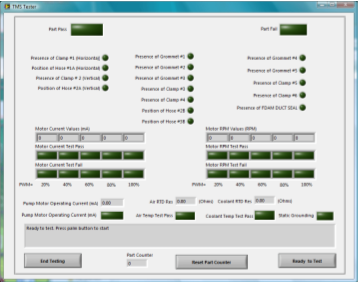

We developed the test software using LabVIEW and CompactDAQ platform from National Instruments. A touch sensitive, panel mounted, Windows computer is interfaced to the CompactDAQ hardware using USB. All digital and sensor signals, directly interfaced to inputs at CompactDAQ modules are acquired, displayed and logged by automation software.

The output modules in the same CompactDAQ chassis are used to generate the PWM signal for motor speed control, voltage outputs to set potentiometers and the digital signals for part placement and holding purposes.

The automation software also interfaces to several vision systems triggering the visual inspection and detection of parts on the assemblies. Results from visual inspection are then included with testing of motor currents at different speeds to validate the assembly quality. All test results are then stored to disk files for post test analysis.

The automation software allows a password authenticated access for test setup and acceptance criteria. It then executes the test sequence, determines the assembly quality and prints a sequential serial number affixed by operators on passing units.

The automation computer and CompactDAQ hardware are all included in a single test cabinet standing next to test fixture and machine vision cameras to provide a rugged and successful production floor test solution.