Playing a leading role in turbine research, Gas Turbine Laboratory of Institute of Aerospace Research (NRC) provides state of the art research facility for characterizing and optimizing fuel injection nozzles for turbine engines. Used by aircraft engine manufactures, the spray dynamics laboratory requires a flexible and reliable test and control automation demanding integration of motion control, monitoring and control of operating conditions, interface with laser based fuel particle size measurement sub-system and extensive monitoring and logging capabilities.

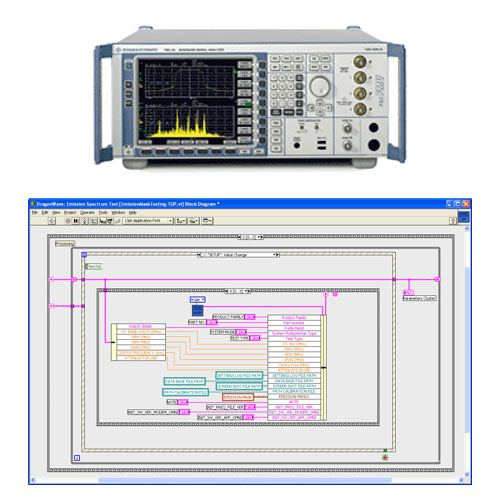

he test application runs on a MS Windows desktop connected to a Rohde & Schwarz spectrum analyzer capable to sweep up to 30 GHz. As the operator scans the unit under test serial number and settings that relate to the type of test, the software automatically picks predefined setup and test criteria from a disk file. The spectrum analyzer is no configured with the emission mask lines and other setup details and becomes ready for the test.

Emission sweep is then run and results compared to the test specific mask. The spectrum analyzer screen shot and all test settings and results are stored in disk files for post test analysis and data is stored in the central results database.

The LabVIEW based test automation code is written with a modularity that is scalable to work with different types of spectrum analyzers. Whereas the code provides an intuitive user interface for just the emission mask testing, the virtual instruments are developed with a reusable architecture and can be used to carry out the instrument setup, test, and results storage directly in a larger test application.

Availability of driver software requiring a very few modifications and other utility software from Rohde & Schwarz made this a very effective development exercise to implement this automated test application.

“WiTEST engineers provided us with cost effective and professional quality automated test software. Their expertise in LabVIEW, instrumentation control and test software integration are highly commendable.”

Baja Nadarevic

Manager, Test Engineering Group. DragonWave Inc.